Zuschneidfelle is a German term combining zuschneiden (“to cut”) and Felle (“skins/hides”), referring to hides specially prepared for cutting and pattern work. These are high-quality leather or synthetic materials designed for accuracy, uniformity, and ease of use in crafting premium goods.

2. Historical Origins & Traditional Context

2.1 Etymology and Early Use

The term originates from German craft traditions: Felle for hides, zuschneiden to cut. Historically, craftsmen selected and tanned hides specifically suited to pattern-based production, minimizing flaws and ensuring consistency.

2.2 Medieval Guilds & Craft Legacy

In medieval Europe, shoemakers and saddlers relied on precise hides to produce durable, tailored goods. Schneidfelle were prized for their strength and clean grain, used in bespoke production—leading to refined manufacturing standards over centuries.

3. Key Characteristics & Types of Zuschneidfelle

3.1 Full‑Grain vs. Corrected Grain

-

Full-grain Zuschneidfelle maintain the hide’s natural surface, prized for durability and patina over time.

-

Corrected-grain hides are lightly sanded to remove imperfections, offering more uniform appearance for mid-tier products.

3.2 Vegetable‑Tanned vs. Chrome‑Tanned

-

Vegetable‑tanned hides use natural tannins, supporting eco-conscious production with aging patina.

-

Chrome‑tanned hides are supple and water-resistant, ideal for industrial goods like belts or bag panels.

3.3 Synthetic Cutting Skins and Modern Variants

Modern zuschneidfelle can also be high-grade synthetics or composites used as cutting mats or templates. These offer durability, stain resistance, and consistent surfaces, especially in mixed-material crafting.

4. Advantages Over Raw Hides

-

Processed for consistent thickness, minimizing waste and cut errors.

-

Ready-to-use with tanning and finishing applied. No soaking, stretching, or preparation needed.

-

Uniform grain and fewer defects lead to cleaner, predictable patterns.

5. Core Applications: From Leather Goods to Upholstery

5.1 Footwear & Saddlery

Zuschneidfelle is essential in high-end shoe and saddle making, ensuring durability, strength, and seamless form-fitting parts.

5.2 Handbags, Belts & Accessories

Used in fashion and accessory sectors to craft handbags, wallets, and belts. High-quality hides lend elegance and longevity to luxury goods.

5.3 Upholstery, Decor & Mixed Media Crafts

Ideal for furniture detailing, decorative leather panels, and mixed-media crafts. Synthetic versions serve as surfaces for precise fabric or fur cutting in upholstery.

6. Cutting Techniques & Best Practices

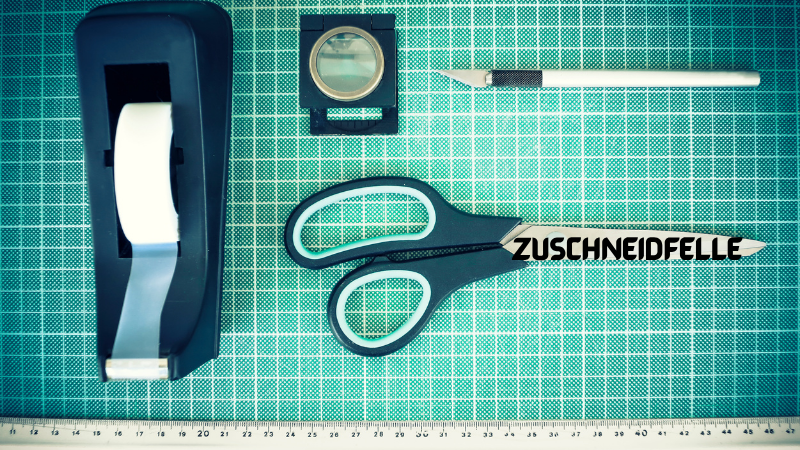

6.1 Tools: Blades, Rotary Cutters & Mats

Professional cuts require sharp rotary blades or utility knives. Using a solid cutting mat—or synthetic zuschneidfelle surface—protects both table and tool longevity.

6.2 Pattern/Layout & Grain Direction

Align patterns carefully with the grain to preserve strength and aesthetic quality. Plan layouts to use hides efficiently and reduce offcuts.

6.3 Minimizing Waste & Maximizing Yield

Strategic arrangement of patterns ensures minimal scrap. In industrial settings, CNC cutters can optimize layouts further, but hand work remains invaluable for bespoke production.

7. Care & Maintenance of Zuschneidfelle Hides

-

Store in cool, dry places to prevent mold or drying cracks.

-

Clean with soft brushes or pH-balanced, mild cleaners.

-

Apply leather conditioners to vegetable-tanned varieties to maintain flexibility.

8. Sustainability, Ethics & Market Trends

In recent years, suppliers emphasize:

-

tracing hides to meat-industry by-products

-

using natural tanning methods

-

reducing waste and promoting ethical sourcing.

Demand for vegetable-tanned Zuschneidfelle is rising thanks to sustainability concerns and appreciation for natural patinas in long-lasting goods.

9. Pricing, Sourcing & Custom Services

Zuschneidfelle generally cost more than average hide due to specialized processing. Prices depend on:

-

hide size & quality

-

tanning method

-

finish & color

-

customization options (size, embossing, consultation services)

Many vendors offer sample swatches and selection support for artisans and designers.

10. FAQs

Q1: What makes zuschneidfelle different from regular leather hides?

They’re pre-tanned, uniform, and optimized for precision cutting. Regular hides vary in thickness and surface quality.

Q2: What leather types qualify as zuschneidfelle?

Full-grain, corrected-grain, vegetable-tanned, chrome-tanned hides—any prepared for cut-use qualifies.

Q3: Can I find synthetic versions of zuschneidfelle?

Yes. Modern versions are engineered composites used as cutting mats or pattern surfaces in multi-material crafts.

Q4: Are these hides sustainable?

Many suppliers now source hides as by-products and use eco-friendly tanning, with certifications and traceability for ethical production.

Q5: What tools are ideal for cutting zuschneidfelle?

Sharp rotary cutters or knives and sturdy mats help with precise, clean cuts; testing on scraps first is recommended.

Q6: How should I store unused hides?

Keep them rolled, in a cool dry environment, away from direct sunlight or humidity. Occasionally condition vegetable-tanned versions.

11. Conclusion

Zuschneidfelle represents craftsmanship, precision, and quality in modern and traditional leatherwork. As hides optimized for cutting, they enable artisans to produce elegant, durable, and consistent leather goods—from footwear and accessories to upholstery. Emerging trends in sustainability, customization options, and synthetic variants only enhance their relevance today. Whether for bespoke design or efficient production, understanding and using zuschneidfelle elevates creative projects to a professional standard.